-

Interior Accessories

Interior trim and styling-

Blackout Tape Matte black tape covers up worn areas like consoles, gauge faces, door panels, etc.

Blackout Tape Matte black tape covers up worn areas like consoles, gauge faces, door panels, etc.

-

Vinyl Wrap Wrap console, door handles, gauges and other interior parts

Vinyl Wrap Wrap console, door handles, gauges and other interior parts

-

Wheel Well Molding Flexible Trim is also useful for interior restorations

Wheel Well Molding Flexible Trim is also useful for interior restorations

-

-

Exterior Accessories

Exterior restyling top to bottom-

Blackout Tape Matte black tape covers scratched window frames and other trim.

Blackout Tape Matte black tape covers scratched window frames and other trim.

-

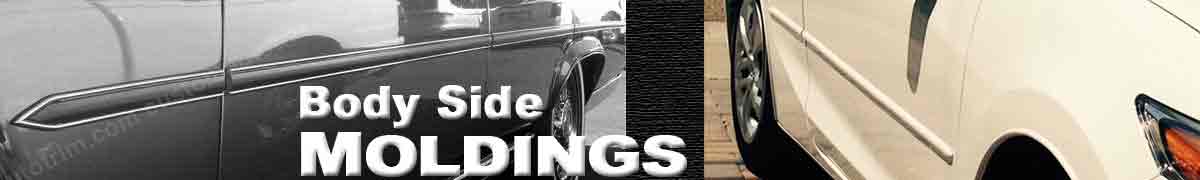

Body Side Moldings Side moldings and protective door trim

Body Side Moldings Side moldings and protective door trim

-

Bumper Protection Molding Front, rear, and tailgate molding

Bumper Protection Molding Front, rear, and tailgate molding

-

Chrome Rocker Panels Lower door and body panel trim

Chrome Rocker Panels Lower door and body panel trim

-

Cross Bars Cross Bars Only. Upgrades your load capacity, attaches to your factory rails.

Cross Bars Cross Bars Only. Upgrades your load capacity, attaches to your factory rails.

-

Custom-Fit Graphics Stripe kits and graphics custom-fit to your vehicle.

Custom-Fit Graphics Stripe kits and graphics custom-fit to your vehicle.

-

Door Edge Molding Protects Door Edges and other Surface Edges

Door Edge Molding Protects Door Edges and other Surface Edges

-

Fender Flares Covers wheel well openings. Factory Style or Extended Width Fender Flares.

Fender Flares Covers wheel well openings. Factory Style or Extended Width Fender Flares.

-

Graphic Kits Graphic decals for vehicles and boats

Graphic Kits Graphic decals for vehicles and boats

-

Hubcaps Wheel Covers, wheel skins and wheel simulators

Hubcaps Wheel Covers, wheel skins and wheel simulators

-

Lambo Doors Lambo door hinges and accessories

Lambo Doors Lambo door hinges and accessories

-

Nerf Bars Nerf Bars, step bars and running boards

Nerf Bars Nerf Bars, step bars and running boards

-

Pinstriping Tape Striping tape for auto, boat and other projects

Pinstriping Tape Striping tape for auto, boat and other projects

-

Rear Window Graphics See-thru window graphics and window screen decals.

Rear Window Graphics See-thru window graphics and window screen decals.

-

Rivet-on Molding Aluminum rivet-on channel molding,vinyl color inserts and end tips

Rivet-on Molding Aluminum rivet-on channel molding,vinyl color inserts and end tips

-

Roof Rack Accessories Accessories and sport equipment carriers for Roof Racks

Roof Rack Accessories Accessories and sport equipment carriers for Roof Racks

-

Roof Racks Factory style and aftermarket luggage & cargo racks

Roof Racks Factory style and aftermarket luggage & cargo racks

-

RT Steps Magnum RT Steps, Black Step Boards

RT Steps Magnum RT Steps, Black Step Boards

-

Specialty Pinstripes Special-design pinstripes and emblems.

Specialty Pinstripes Special-design pinstripes and emblems.

-

Truck Bed Rails Stake pocket mount and drill mount side bed rails available in many styles

Truck Bed Rails Stake pocket mount and drill mount side bed rails available in many styles

-

Vinyl Wrap Carbon Fiber, Wood Grain and more to wrap your car

Vinyl Wrap Carbon Fiber, Wood Grain and more to wrap your car

-

Wheel Well Molding Universal flexible trim molding

Wheel Well Molding Universal flexible trim molding

-

-

Chrome Accessories

Interior & exterior chrome styling-

Body Side Moldings Chrome Side Moldings and Universal Trim

Body Side Moldings Chrome Side Moldings and Universal Trim

-

Chrome Rocker Panels Add chrome to Lower Door and Body, Vehicle-Specific-Fit Kits

Chrome Rocker Panels Add chrome to Lower Door and Body, Vehicle-Specific-Fit Kits

-

Nerf Bars Stainless Steel Nerf Bars and Step Bars

Nerf Bars Stainless Steel Nerf Bars and Step Bars

-

Truck Bed Rails Stainless Steel Bed Rails

Truck Bed Rails Stainless Steel Bed Rails

-

Universal Chrome Trim Universal Cut-to-Fit Wide Chrome Trim

Universal Chrome Trim Universal Cut-to-Fit Wide Chrome Trim

-

Wheel Skins Molded Chrome skin covers for Factory Finished Wheels

Wheel Skins Molded Chrome skin covers for Factory Finished Wheels

-

Wheel Well Molding Chrome flexible trim molding for exterior & interior uses

Wheel Well Molding Chrome flexible trim molding for exterior & interior uses

-

-

Graphic Decals & Wrap

Graphics, stripes and vinyl wrap-

Blackout Tape Matte black tape to wrap door handles, light bezels, emblems, etc.

Blackout Tape Matte black tape to wrap door handles, light bezels, emblems, etc.

-

Custom-Fit Graphics Racing stripes and graphics custom-fit to your vehicle.

Custom-Fit Graphics Racing stripes and graphics custom-fit to your vehicle.

-

Graphic Kits For vehicles, boats and other uses

Graphic Kits For vehicles, boats and other uses

-

Pinstriping Tape Cars, trucks, boats and other uses

Pinstriping Tape Cars, trucks, boats and other uses

-

Rear Window Graphics See-thru Rear Window Decals and window screen decals.

Rear Window Graphics See-thru Rear Window Decals and window screen decals.

-

Specialty Pinstripes Specialty pinstripes and emblems.

Specialty Pinstripes Specialty pinstripes and emblems.

-

Vinyl Wrap Carbon Fiber, Wood Grain and other Finishes for your wrapping project

Vinyl Wrap Carbon Fiber, Wood Grain and other Finishes for your wrapping project

-

3/8 Inch Round Wheel Well Molding Chrome 20 Ft Or 125 Ft Rolls.

- Width: 3/8 inch tall

- Style: Half Round Style

- Length: 20 Ft or 125 Ft Roll

- Thickness: 3/16 inch

- Material: OEM approved Vinyl with 3M adhesive tape

March 07 2026

March 07 2026

Chrome Round flexible trim molding protects vehicle wheel well openings and adds a decorative accent. Larger rolls are suitable for projects where flexible trim is needed to hide seams and provide edging trim to most surfaces.

-

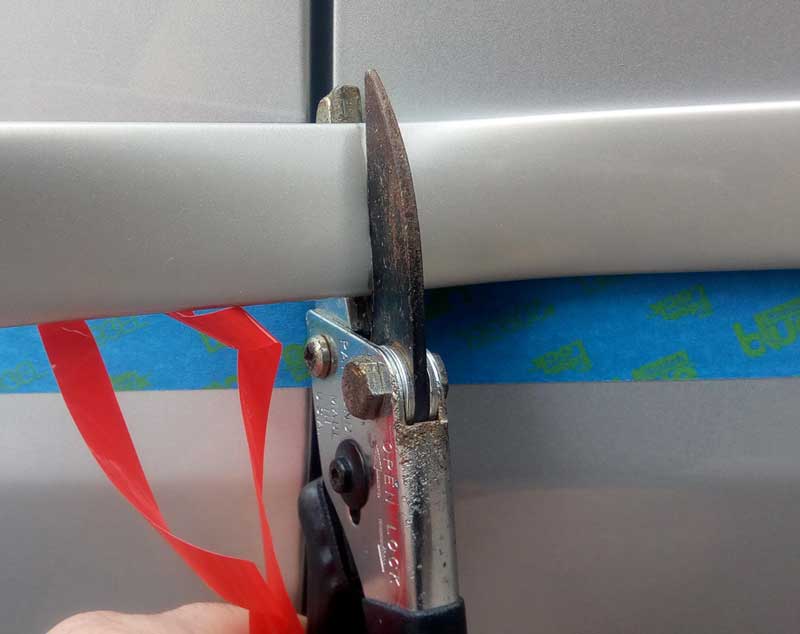

Once you have properly prepared the surface and set down your masking tape guideline, apply adhesive promoter to the vehicle surface where it will make contact with the molding. This will increase the bond of the adhesive as the molding gets pressed into place.

-

Peel back the red liner of the roll of molding about 18 inches to expose the adhesive so you can work one section at a time. Position the molding right below the masking tape, using it as a guideline.

-

Push the end of the molding down with the back of your hand to set in place. Then continue to press down, sliding along with the palm of your hand using medium pressure .

-

When you come to the door break, cut the molding with a straight blade shear just short of the door edge. Continue applying the molding on the quarter panel; when you get close to the wheel well, cut the molding at an angle to match the wheel well opening.

-

Go back and press down using very firm pressure, sliding along with a soft cloth to protect your hand. Continue this process again a second time using more pressure. (You can also use a rubber roller tool for this process). Finally, remove masking tape guideline.

This is an example of a finished install using our 1 ½ inch Body Side Molding MDG117.

AUTOMEGA® Body Side Moldings Installation Demo

- It is important to be sure the edge is clean and free of dirt; be sure to clean underneath the wheel well opening. Use rubbing alcohol to finish prep the area.

- Estimate length needed by unrolling molding around the wheel well. Mark the needed length with wax pencil or score with a knife. Trim the excess with a sharp knife or molding shears (garden anvil type pruning shears work just fine).

- Remove the backing liner so the adhesive side is exposed. Application works best when using both hands, one to position and the other to spool out and maintain angle.

- Press lightly at first so you can reposition if you happen to get off the curve.

- Burnish by pressing firmly to help adhesion. You'll be pleased with this OEM look.

Wheel Well Molding Installation

Ships USA, Canada and other International destinations. We will provide a freight quote to international destinations.

Ships from our USA Warehouses located coast-to-coast. Delivery time approx 1-3 business days.

- Credit Card Payments: We can ship all items to a different address from your billing address, except for 'Tagged' items.

- Money Orders: we can ship to different addresses if paid by Money Order.

- Tagged Items: Body Kits, Lambo Dr Kits, high value and other tagged items can only be shipped to an address that is on account with your credit card company.

If you wish to ship to a different address than your billing address, you can call your credit card company and ask them to add an alternate or temporary shipping address to your account for the transaction. (Adding this temporary address will not change your official address, it will only give your bank notice that you are authorizing a shipment to an alternate address.) Once we verify your alternate address with your credit card company, we will be able to obtain an authorization to charge your credit card. - Billet Grilles: 25% restocking charge.

- Body Kits: Restocking fees of 25%-30% depending on each Manufacturer Brand.

- Fender Flares: 25% restocking charge.

- Lambo Door Hinges: 25% restocking charge.

- Nerf Bars/ Step Bars: 25% restocking charge.

- Stainless Steel and Chrome Products: 25% restocking charge.

- Rear Window Graphics: Rear window graphics are custom made to order. All Returns and Exchanges are subject to a 20% restocking charge. Customer is responsible to accurately measure the outside of the window to determine the appropriate size graphic before placing order.

TERMS AND CONDITIONS OF SALE:

USE OF WEBSITE

By entering our web site, you agree to comply with the terms and conditions set forth below. If you do not wish to be bounded by these terms and conditions, you may not access, use or purchase from this site either online or by phone.

If you submit an order online and have checked the box stating that you have read and agreed to our Terms and Conditions of Sale, you are agreeing to be bound by these terms. If you do not agree to these terms and conditions, you must not submit or finalize your order, and you may not access, use or purchase from this site either online or by phone.

Our products are advertised for sale exclusively online. Our terms and conditions are posted conspicuously - if you place your order by phone you are also agreeing to be bound by these terms and conditions. If you do not agree to these terms and conditions, you must not place your order and you may not access, use or purchase from this site either online or by phone.

RESPONSIBILITY OF PURCHASER

Customer is responsible for selecting the correct part number for their vehicle. We assume no liability or incidental costs incurred for wrong parts purchased.

All products sold on this web site are strongly recommended to be installed by professionals in the automotive trade who are experienced in installing the particular product that they purchase. Anyone who purchases from this site, including consumers, re-sellers or installers, are accepting responsibility for the proper installation of these products. Consumers are advised to use an installer that warrants their labor against improper installation.

PAYMENTS

All items must be prepaid prior to shipping, we do not ship C.O.D.

We accept payments by Money Order or Credit Cards (no international credit cards).

Billing Addresses for Credit Card Payments

We require your official billing address listed on file with your credit card company in order to obtain an authorization to complete your order even if you ship to a different address.

Shipping to Different Addresses

CUSTOM/ SPECIAL ORDERS

Custom or Special order items require prepayment before shipping.

Custom or special order items are items that are made to order, painted to order, special size or other non-stocking items.

CANCELLATIONS

Cancellations, after processing your order, if allowed, are subject to a cancellation fee similar to restocking charges if the order has not shipped.

If your order has shipped before notice of cancellation, shipping charges will not be refunded and you will need to request a return and obtain a Return Authorization Number, if the return is allowed as described under "Returns" below.

REFUSED DELIVERIES/ RE-DIRECTED SHIPMENTS

Refused merchandise at time of delivery will incur return freight charges in addition to cancellation or restocking fees.

Customer is responsible for all charges associated with re-directed shipments..

PRODUCT INSPECTION

It is the customer's responsibility to open the package and inspect the items upon delivery. Packages that appear to be damaged should be immediately reported to the freight carrier. Damage due to shipping is the sole responsibility of the freight carrier. All claims are to be made by the customer directly with the carrier. Shipping carriers will not honor late claims.

TEST FIT PARTS (DRY FITTING)

All items should be inspected for defects or damage and "dry fitted" prior to being installed. Installation instructions provided should be followed completely.

We recommend that all items be professionally installed. Any concern or question as to fit or installation should be brought to our attention. We provide technical support during our normal business hours to help with installations.

All reasonable attempts should be made for proper installation before making a return claim. It is our sole discretion to authorize returns for credit or exchange.

RETURN POLICY:

REQUEST FOR AUTHORIZATION

We must be notified of all return claims within 7 days of delivery date of your order. You must call us first to obtain authorization for the return. We will give you instructions on how to ship the return. Do not return items without prior authorization. We will not accept shipments to us without a confirmed Return Authorization Number.

Absolutely no returns will be accepted after 30 days.

Items must be returned in its complete new, unused condition for credit.

Package and Insure Items/ Condition of Parts

If you are instructed to ship your return prepaid, the items must be shipped back within 10 days and insured for its full value against loss or damage. Any items shipped freight collect will be refused and returned to you your expense.

All items authorized for return must be carefully packaged in its original carton including all packing material, or in another box that is suitable to protect its contents.

It is important that you insure your package against shipping damage in transit as items returned in scratched or damaged condition will not be credited. If items are damaged in shipment, you will have to make a claim with your shipper to recover the cost of the item.

CREDITS

Items must be returned in its unused condition for credit. Items not in new, unused conditions will not receive credit.

Shipping and Handling charges are services performed and completed at time of original delivery and are non-refundable.

Items returned under warranty will be exchanged or credited at our option. Liability is limited to replacement value of the

NON-RETURNABLE ITEMS:

Custom or Special Order items are not returnable (Custom or special order items are items that are made to order, painted to order, special size or other non-stocking items).

Painted Orders are not returnable.

Items cut-to-order, such as moldings and vinyl wrap are not returnable.

Clearance Sales: All sales are considered FINAL; clearance sale items are not returnable.

RESTOCKING CHARGES

Restocking charges are fees incurred for inventory control, administration and handling of returns.

Any item, except as described below, returned for any reason other than what is covered under warranty will be subject to a 20% restocking charge.

LIMITATION of LIABILITY and DISCLAIMER

The AUTOMEGA® web site (www.CustomAutoTrim.com) and the materials therein are provided "AS IS". AUTOMEGA® makes no representations or warranties either express or implied, of any kind with respect to the operation, contents, information, or materials contained therein. You agree that AUTOMEGA®, its directors, officers, employees or other representatives shall not be liable for damages arising from the operation, content or use of the AUTOMEGA® web site. You agree that this limitation of liability is comprehensive and applies to all damages of any kind, including without limitation direct, indirect, compensatory, special, incidental, punitive and consequential damages.

WEBSITE IMAGES

Please be aware that all cars depicted on the website are highly customized cars. Each car has had many modifications made to them including painting and possibly altering of the depicted kit. Please read the description of the part carefully as one or more of the kit options may include a different part then depicted in the image. The depicted parts may have extra work including, but not limited to, molding, cutting, or adding to the original piece. Parts such as lights, splitters, canards, paint, and others accessories are not included unless specifically specified in the product description.

TYPOGRAPHICAL ERRORS

In the event a product is listed at an incorrect price or with incorrect information due to typographical error or error in pricing or product information received from our suppliers, AUTOMEGA® shall have the right to refuse or cancel any orders placed for product listed at the incorrect price. AUTOMEGA® shall have the right to refuse or cancel any such orders whether or not the order has been confirmed and your credit card charged. In any event if your credit card has already been charged for the purchase AUTOMEGA® shall immediately cancel the order and issue a credit.

COPYRIGHTS/TRADEMARKS

All of the contents on this site including graphics, text, logos, button icons, images, audio/video clips and software belongs to AUTOMEGA® and are protected by U.S. and international copyright laws. Any unauthorized use of these materials may be a violation of copyright, trademark and other applicable laws and could result in criminal or civil penalties.

AGREEMENT

This agreement shall be governed by, construed, and enforced in accordance with the laws of the State of California. Venue for any action or proceeding arising out of this agreement, or alleged breach thereof, shall be solely in San Diego County, California, within the City of San Diego, California.

AUTOMEGA ® is a registered trademark of Custom Auto Trim and Graphics, Inc. COPYRIGHT ©1996 - 2014. Custom Auto Trim and Graphics Inc. All rights reserved.

AUTOMEGA® CustomAutoTrim.Com TESTIMONIALS

Clinton H. writes:

Got my order thank you very much for the prompt response. The order [Pinstripe] was perfect , the person that took care of my order was very helpful and making the order was very successful. Thank you ever so much!

Ted Nagorski writes:

Received my order today and am absolutely, positively pleased with the body moulding. This is an exact duplicate of what the truck has originally equipped with. Thanks so much for the fast shipping.

Larry Hatch writes:

..Thank You. Received my Door Trim yesterday. Very high quality. Great service and 2 day shipping. Excellent job.

Dianne Tyler writes:

( Rear Window Graphic RWG1954 ) I love it! It arrived fast! Looks amazing! Was easy to install! Thanks!

Janette Fontaine writes:

Hi, just wanted to show you how great the skull [Part# RWG1999] looks on my 69 VW Beetle. We have gotten quite a positive response from the look of it. Thank you for taking the time to work with us.

Stuart Gray (Australia) writes:

Hi The parts I ordered have just arrived you have given the best service I have ever received from any US supplier. Thank you.

Keith Brown writes:

I just installed the Supra style [spoiler] on my car today and it looks amazing! I had a 1991 Supra turbo along while back and love them. I have a 2002 Volvo c70 convertible now.... and needed something to make it pop. I wanted a Supra style [spoiler] and you guys were the only ones that had it. I don't normally email after a sale but was so happy with the whole thing and wanted to thank you guys...

Chad Hicks writes:

Just wanted to say thank you for the super fast service and shipment of the [body side] molding I ordered. I received the package in less than a full business day. Will be using you again if my shop has the need.

Narelle Thompson writes:

In June 2015, I purchased the vinyl insert trim from Custom Auto Trim.

I have a 1965 Ford GT Mustang that has the channel molding with the vinyl insert trim on the side [body] panels, which was a dealer option in 1965. The vinyl insert trim was original, faded and perished. After a frustrating search I was unable to source the vinyl insert trim in Australia and found Custom Auto Trim [CustomAutoTrim.com] had the same style. The Custom Auto vinyl insert [Part# INSERT] was a perfect fit slotting in the original aluminium channel molding and now the car looks fantastic.

Your service was fast and the communication was excellent. I have attached a few pictures of the before and after just so you can see the difference and how fantastic your trim looks on this 50 yr old vehicle. Thanks again for a great product and fantastic service. 1965 Mustang 'Before' Pic 1965 Mustang 'After' Pic 1 1965 Mustang 'After' Pic 2

Wes Doty writes:

I am very pleased with my order [graphic kit] and I will order from you again and I am going to order for my wife's vehicle..

Mike Marsico writes:

Anita, Wow thanks for the nice part you sent me. It worked out fantastic!!!

David Arrendondo writes:

Thank you very much for such great service. I received the rare rivet-on trims and couldn't be happier.

Kyle Miller writes:

Nice site... I found the perfect graphics for my 1998 ford expedition. My kids are going to be surprised!

Kirk Fritz writes:

I would like to commend Anita for her customer service with respect to my selection on a side molding through AUTOMEGA. She took the time to navigate with me through the web site to get the right product for my needs. Many service agents in her position have an "it's up to you" attitude, and Anita had a proactive "the right product for you" attitude. I thank her, and the molding looks and works great so far.

Dave Barickman writes:

I just wanted to thank you for the great service and VERY quick shipping on the trim [body side molding]. It arrived in Kansas City in two days and was at my door yesterday when I got home. The trim looks great and will work very well on my vehicle. Thanks again!

David Goodwin writes:

Just thought I'd drop you a note to compliment you on your website. It is one of the most pleasant sites I've visited in my quest for Scout accessories. Your use of the colors and animation are well done. Navigation is efficient and all graphics and lettering are easy for these 50-year-old eyes to read. Keep up the good work!

Kathy Schad writes:

I just wanted to tell you how pleased I am with the graphics kit that I ordered from you. It was very easy to install, and really makes the car stand out, not just another white car on the road. I have had many people tell me how much they like it too. I used the extended pieces under the tail lights. I attached 2 pictures to show how the graphics looks on a Pontiac 08 G6 GXP.

Glen Porter writes:

Anita, I really enjoyed talking with you and wish to thank you for such a professional job in handling my order in such a fast time. I don't think I have ever received any better or faster service in my life! I received the rocker panels yesterday and put them on last night; THEY LOOK GREAT!! I am real satisfied with the high quality of material and workmanship and would gladly recommend your products to anyone else who might be interested.

Jeffrey G. Riblett Sr. writes:

I just wanted to let you folks know how pleased I am with my new spoiler and with the experience of buying from you. Two days after placing the order one of your employees called me at home because the paint code I gave didn't match the name of the color. He spent a few minutes on the phone with me helping me find the correct code on the car and explained how things work with painting plastic parts. I was very impressed at that. Customer service means a lot to me and your folks went above and beyond the call of duty. I received the spoiler today via UPS and was very pleased with the packaging and the paint is a dead perfect match! I am very pleased and have stated as much on the Thunderbird and Cougar Club of America (TCCoA) BBS page. I'm sure you will be getting orders from some of our other members. Thanks again for a great product and experience!

Dan Kranker writes:

Hi Anita, Thanks for the prompt, efficient, courteous service. I truly appreciate dealing with a customer service person who not only understands the product, but knows how to talk to people. Dealing with your company has thus far been a pleasure, which is entirely because of your involvement. Now I only hope the product is as nice as the customer service rep!

Nick Griffin writes:

Here it is finally done, the paint job turned out pretty good, after all the time and work it took us to get it here. Feel free to do what you will with these pics, just thought you would like to see were the spoiler was going, once again thanks for the help, I greatly appreciated your service. It is not easy to find good customer service. Pic 1 Pic 2

Gina DuQuesnay writes:

Thanks so much for taking care of [..hub caps]. I looked at what you picked out. Great choice, will work just fine. I really appreciate your help with this. You really went above and beyond customer service. Just wanted you to know that I would recommend you guys to anyone and I would do business with you again. Have a great day.

John Horton writes:

I ordered the unpainted molding [MDG145 UNF ] as you suggested and my local Ford dealership painted it to match my Sport Trac and installed the molding...it looks great, in fact Ford should produce the Sport Trac with this "look", it actually enhanced the appearance of my truck.

George Stevens writes:

I cannot believe that not only did you acknowledge my question from a prior email, but a young lady called me minutes ago to inform me of the status of this order. Not only am I impressed with your customer service, but considering you are an internet based company, the mere fact that you called tells me that you are customer oriented. Any time that I need an accessory or whatever, that can be purchased thru your company, I will buy it from you. Brand loyalty...........well, try company loyalty, for you earned a life long client.

Robert Armstrong writes:

I just ordered it Tuesday, and today, Thursday, I have it. OUSTANDING! SUPER SERVICE! EXTREMELY IMPRESSIVE!

Matt Turner writes:

I ordered body side moulding for my 2009 Silverado. I am very pleased on how it turned out. Even someone like me, with all thumbs, managed to install body side moulding that looks factory installed! Your instructions are easy to follow and your service was fast. Thanks again!

Charles White writes:

My order came in Thursday, I ordered it Wednesday. Great job! I thought I would be waiting till after the Holidays for this. Good company!

Jim Trail writes:

Here is photo of my Grandson's 1985 S 10 Blazer that I put the graphic kit on. Was it easy, no but then tell me when anything easy is worth a hoot. Did require a few extra miller lites. When I saw the look in my Grandson's eyes, when he first saw it, I knew it was all worth it! Thanks for a great kit.

Kennett Wells writes:

I wish to let you know how pleased I am with the product and timely delivery. I've searched high and low to find the product to fill my requirements. '06 2500HD, Crew cab with long bed and wheel to wheel bars. These really look great on my truck and they were relatively easy to install. Thanks again.

April Barabe writes:

I received my order yesterday and I must say I am very happy with not only the product but the customer service. The item that you recommended [hood scoop] for me was a perfect match. If only more business' practiced like you. I look forward to many more future purchases through you and I will recommend you to all my friends. Thank you.

Mark Levine writes:

Very satisfied with product and service. Received my order of molding MDG 148 today. It matched the factory molding very closely. Thanks for the fast delivery service. I called customer/technical service several times and received courteous and prompt answers to my questions.

Stephen Morrison writes:

Hi, I would like to thank you for the fast delivery of the headlights. They look great and hopefully will be easy to install. Thanks again I have recommended your website to many of my friends!! Thanks again Stephen

Steve Gabele writes:

Just wanted you to know that I got the ramp Wed ( 2 days ago) with plenty of time to spare. Made for a little less stress on this end. I appreciate the email also giving me a heads up. Thanks so much for the hussle, I really appreciate it. That's GOOD CUSTOMER SERVICE.

Vazgen Khrimian writes:

First time I've been contacted by a customer service team without having to call once or twice first. You guys have some nice [Customer Service].

Robert L. Eisenman writes:

I just wanted you to know I had this hood scoop painted and installed and it looks great. Thanks for the fine quality product !

Peter Katowicz writes:

In the last week I called your company, and had an email response later that day, then I had more questions which I sent via email, and those were answered the next day. Thanks for your fast turn-around time, what a great company to buy from!! Keep it up please!!

Richard Lee writes:

Just wanted you to know I received my order as scheduled. I am very happy with the speed of service. I got the order at 10 am today and at 11 am I am enjoying the installed lights. Thank-you again for the excellent service.

Robert Nolan writes:

Hi, WOW!!! I received the Altezza Tail Lights for my 2002 Grand AM GT, I couldn't believe how simple it was to install, NO TOOLS!! I am so very pleased with the new look it's unreal, the clear chrome on a silver pontiac makes a statement ... thanks so much.

P.S. 2 years ago I purchased side graphics for my 2001 SPORT TRAC, and I still get complements to this day, I guess I put on some impressive look, thanks to you..

William J. Beers writes:

Shipment arrived on Thursday, Nov, 21. Was quite pleased with the stylish look and ease of installation. The bars lined up perfectly. I do wish the instructions were a little more clear but that's probably the learning curve for ya.

Thanks so much for a quality product and excellent service. I especially appreciate the call to clarify the exact style of my truck to make sure the product fit.

Larry Kelley, winner of our newsletter contest {received a FREE AUTOMEGA car duster} writes:

Thank You very much! I really appreciate the prize, I use it on my car everyday & it works great. I will contact you when I need things for my Honda Accord . I told all my friends about your company.

Kevin Stoy writes:

Thanks again for the great [service] and quality on my spoiler for my 1995 Ford Probe, we painted it and mounted it, and it looked and fit perfect!

Juan Espinoza writes:

>Thank You Very much for the Ford Explorer tails Lights, I am very satisfied by my buy...

Daniel J. Bell writes:

Just wanted to send all of those involved with my order a note of thanks for the fine service I received. My order arrived 1 day earlier than estimated, it was sent out promptly, and the fit of the part on my truck couldn't had been any better if it had been made by Mopar! I will be back to do more business with your fine company in the future. Thanks again and have a great day!

Tony McJilton writes:

Here are the answers [to the contest]... hope [I win] the sweatshirt . X Large works . Thank you so much for taking the time to put together a great website with lots of info and good deals.

Craig Waterstreet writes:

Thank you for your prompt quality service! I will refer others to your business.

Dennis Maltais writes:

Just received my order the other day - a painted custom spoiler for my Toyota. It arrived in perfect condition, the paint was beautiful, and for anyone with a little mechanical ability, the installation was very easy. I am extremely satisfied with your product and your service. Thank you.

Bob Heinz writes:

… the air dam is better than I expected. I've owned my '72 240Z since '79 and have had many air dams before.. I always wanted one that wasn't fiberglass and was I pleased when I saw the new one!

Leroy Stevens writes:

You rule...I love the bed rails for my s-10 and they aren't even installed now, just sat them on the bed and it looks great, the measurements were perfect and the delivery was super fast. I got mine 1 week earlier than expected. thank you CUSTOM AUTO TRIM for your prompt service and for making my anniversary and mothers day complete. my wife loves my truck too.

Adam Apodaca writes:

Thank you for your timely service. I appreciate the rush order. I am glad I did business with you.

Michael E Zukowski writes:

I'm sending a Picture of My 2000 Daewoo Leganza again, with your graphic kit on it. I am very pleased with the quality and the look. Thanks.

Michael Spradlin writes:

I was extremely pleased with my order. I placed the order on Sunday night and received the order on Wednesday night. I thought this was extremely quick coming from the West Coast to the East Coast. My neighbor is the manager of an auto body shop and he was complementing the quality of the airbrushed vinyl graphics I purchased. I enjoy watching heads turn as I drive by. Even after a month, I still smile every time I see my truck with the new graphics on. I've enclosed a couple of pictures of my truck. Pic 1 Pic 2

Douglas Cabaniss writes:

Dear Sirs, I too am a happy customer. I ordered one of your graphics packages a few weeks ago. It shipped really fast, was a breeze to put on with your online video help, and looks absolutely great.....or so sez all my friends and myself!!

The enclosed photos are yours to do with as you like. Pic 1 Pic 2

Keith writes:

Thank you!!!!! I received the package today, and I'm very pleased. Thank u so much for the great product and service. I will look forward to doing business with this company again some time soon.

Paul L. Gaiser writes:

I would like to extend my thanks for the prompt processing and shipment of my order. The dash Kit looks great and I can't wait to see it when it's installed.

Jule Malowitz writes:

Suzanne: I would like to take a moment to thank you for convincing me to purchase the wood grain kit for my Hyundai Santa Fe. My overwhelming apprehensions regarding the installation were easily put to rest after I finished the project. It really was not difficult but definitely detailed and time consuming. The job came out great and looks like a factory finish. Your company also needs a round of applause for expediting the order. I'm not sure where else one could get better service on the Internet. The kit was ordered on January 24th and received at my doorstep on the 25th… I will look forward to dealing with you in the future.

Jack Orlando writes:

Hi. Just a quick note: I installed my Wood Trim package on my 2000 Olds Alero dash, doors, etc. After very careful prep (Which I know is of most importance because I am in the business of epoxy coating supply), it took me about 45 minutes to install the various pieces. I started with the simplest piece and worked my way up to the more intricate piece which went around the radio, AC, etc. controls in the center of the console. I am happy to say that it came out quite well, and it really gives the interior of my Alero that luxurious, custom look. People who have seen it, think it came from the factory with the wood trim. I am very pleased with it. Thanks for offering such a well made package, with very clear and concise instructions.

Robert Del Russo writes:

I purchased a wood dash kit from your company last month. I belong to a car club on the internet specializing in Oldsmobile Alero owners. My car is featured on the cite and the members have shown a particular interest in my wood grain kit . . where I bought it and how I installed it etc. I thought your company might be interested in knowing that I posted the information on the cite and included a link to AutoMega. You may want to visit the site and see what I am talking about. I am enclosing the picture I took of the kit installed in my car you may like to use it to help your Alero customers see how nicely this particular installation looks. Pic 1 Pic 2

Dan Dyer writes:

The wheel covers were exactly what I was looking for. Thanks for great service, will add your Co. to my web list and will contact you if I need anything else you carry.

Jim Sheltraw writes:

Good Afternoon, Received my order for a spoiler for my wife's New Beetle this morning. My compliments on the promptness of the order, and the quality of the product. Color match is perfect and the finish is flawless. Can't wait to get it on the car. Thanks for your service.

Joey O writes:

I Installed the dash kit in my 98 Eclipse following instructions to the letter. Couldn't have been easier and it looks great. Thanx for your assistance, and I will certainly recommend you to others who will undoubtedly ask where I got it from.

John Leader writes:

I installed my Carbon Fiber Dash kit from Custom Auto Trim this weekend and my New Beetle looks great. As a thank-you to your company for its reasonable price and your friendly, personal service. Again, thanks for your encouragement...you were right...it was easy!

Charles Webb writes:

Today, I installed the wood dash kit I received from customautotrim.com and I am very satisfied with the quality of the product. I feel the install looks just as well as the wood dash kits I have saw installed on other Toyota's from the dealership as a "port installed option".

Rick Van Leeuwen writes:

The parts came yesterday. Perfect match. They look terrific - really completes the console in my Land Cruiser. It was interesting how they shipped them, all laid out on a piece of cardboard. Anyhow, thanks so much for customizing my order. I'll keep you in mind if anyone asks "Where did you get that beautiful wood dash?"

Michael Estey Jr. writes:

I received my order and I am very happy with your products and your company. Your prompt delivery was appreciated, and I plan to encourage others to order from your company.

William Gonzalez writes:

Boy, those five days sure went by fast because I received the kit the next day of my order. Thank you very much, the wood kit is very nice and I have already installed it on my 4Runner.

Kasha Adrian Hall writes:

Thanks a BUNCH! If the product quality/warranties are anywhere near as good as customer support, I will be EXTREMELY impressed.

Carl Dolinka writes:

I received my wood package and installed it myself. It arrive promptly, installed easily, and looks great. Thanks for your help.

Dan M writes:

It was a pleasure doing business with your company today. My daughter will be thrilled to get the spoiler for her Integra. Thanks again, Dan

Christopher Lewis writes:

You guys rock!!! Spoiler came fast as [****] and it looks awesome. Went on the car without any trouble and looks great! Perfect color match, highly recommend & will buy from you again!!

William Valdez writes:

Hey just wanted to say thanks for the [Xenon] body kit. I recieved it just when you said I would, the price was awesome thanks alot. . . pleasure doing business.